A sturdy and well-built subframe is essential for the longevity and stability of your decking. Whether you’re planning to install composite decking or any other type of decking material, the quality of the subframe is crucial.

In this guide, we’ll cover the dos and don’ts of subframe installation for decking, drawing from industry best practices and guidelines.

Don’ts of Subframe Installation

Skimp on Materials

Avoid using substandard materials or cutting corners to save costs. Invest in high-quality pressure-treated timber and corrosion-resistant fixings to ensure the longevity and stability of your deck.

Neglect Ground Preparation

Skipping proper ground preparation before subframe installation can lead to expensive issues. Avoid uneven settling, poor drainage, and weed growth, compromising the integrity of the subframe and decking by with careful preparation. Take the time to level the ground and install adequate ground protection before laying the subframe.

Overlook Proper Spacing

Improper spacing of joists can result in uneven decking, sagging, and structural instability. Follow the manufacturer’s guidelines and local building codes to determine the correct spacing and support requirements for your decking project.

Forget to Seal Exposed Ends

Exposed ends of pressure-treated timber are susceptible to moisture absorption and rot. Seal the cut ends with a suitable wood preservative or end sealer to protect them from water damage and prolong the lifespan of the subframe.

Dos of Subframe Installation

Start with a Level Surface

Install Ground Protection

Place a layer of landscape fabric or weed membrane over the ground surface before subframe installation to prevent weed growth and moisture build-up underneath the deck. This helps to improve drainage and airflow, reducing the risk of rot and decay in the timber subframe.

Choose Pressure-Treated Timber

Opt for pressure-treated timber for the subframe, as it is resistant to rot, decay, and insect damage, ensuring long-lasting durability. Use timber that is suitable for outdoor use and meets the relevant industry standards for structural integrity.

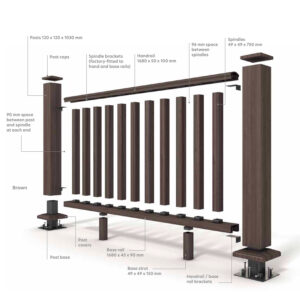

Use Proper Spacing and Support

Space the joists at regular intervals to provide adequate support for the decking boards, typically between 16 to 24 inches apart, depending on the decking material and load requirements. Install support beams perpendicular to the joists to distribute the weight evenly and prevent sagging or warping over time.

Use Stainless Steel or Galvanised Fixings

Use stainless steel or galvanised fixings, screws, and brackets to secure the subframe components together. These corrosion-resistant materials ensure the structural integrity of the subframe and prevent rust and degradation over time.

Now you know how how to prepare the foundations for decking subframe installation, shop our stunning range of decking on our website.

Taking the time to properly prepare the ground, use quality materials, and adhere to spacing and support guidelines will result in a durable and long-lasting deck that you can enjoy for years to come.

When installing composite decking, always revert to the fitting instructions for the best possible finish.

Guardian Extension

The most advanced, energy-efficient pre-assembled building system available, to create a comfortable and affordable living space in half the time of a conventional build.s.

Window and Doors

The best of both thermal efficiency and style in our range of aluminium windows and doors.

Alitherm Windows

Designer Doors

Sliding & Bifold Doors

Open up an entire room to frame the beautiful view of your garden with our range of lift and slide and bifold doors.

Roof Finishes

Our innovative roofing systems combine practicallity with enhanced performance for a beautiful roof.